![]()

GUMMETAL® was developed at Toyota Central R&D Lab in Japan with properties close to rubber: a perfect balance between flexibility and stiffness. Nickel free βtitanium alloy made of Titanium (Ti), Niobium (Nb), Tantalum (Ta) and Zirconium (Zr).

GUMMETAL® has a large elastic deformation range with good formability and a very low Young’s Modulus (soft) with enough stiffness.

GUMMETAL® wire (square/rectangular) can be used to give torque control at the earlier stage in treatment because of its high flexibility. Full size wire can be used to achieve the active torque control because of its moderate stiffness and optimum recovering ability. Maximum activation of the wire is available because of its very wide elastic deformation range.

Because of GUMMETAL®’s excellente bend capabilities it substantively eliminates the necessity of wire changes after leveling. Because of GUMMETAL®’s ultra-low young’s modulus the complicated wire bending is no longer necessary. Because of GUMMETAL®’s high flexibility and formability is advantageous to use with smaller inter-bracket distance such as in lingual technics.

GUMMETAL - Introduction

GUMMETAL - Discrepancy Elimination

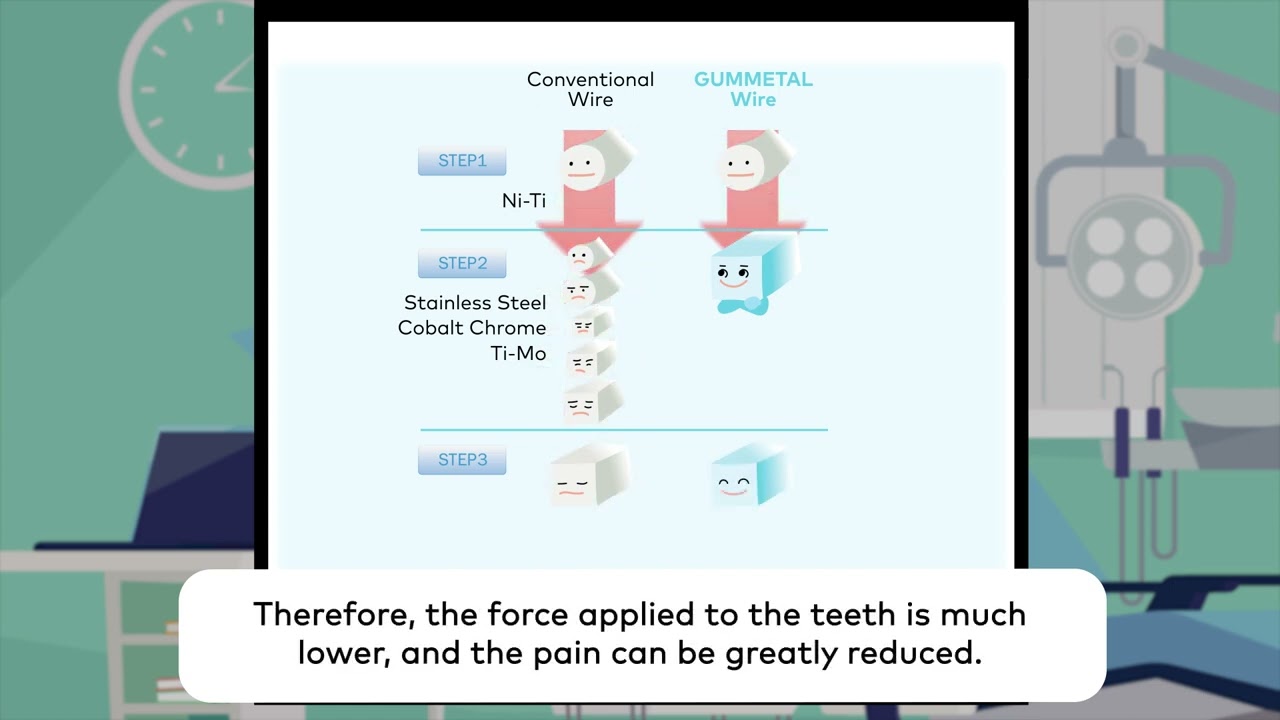

GUMMETAL - GUMMETAL vs Other Wires

GUMMETAL - Characteristics of GUMMETAL Wire

GUMMETAL - Benefits of Choosing GUMMETAL